Regional Sustainability ›› 2022, Vol. 3 ›› Issue (4): 319-334.doi: 10.1016/j.regsus.2022.11.003cstr: 32279.14.j.regsus.2022.11.003

• Full Length Article • Previous Articles Next Articles

WANG Jiguanga,*( ), HU Yushanga, WU Yucaib,*(

), HU Yushanga, WU Yucaib,*( )

)

Received:2022-08-20

Revised:2022-10-28

Accepted:2022-11-29

Published:2022-12-30

Online:2023-01-31

Contact:

WANG Jiguang,WU Yucai

E-mail:wangjg@sxu.edu.cn;wuyucai@sxufe.edu.cn

WANG Jiguang, HU Yushang, WU Yucai. Optimal decision-making considering inter-supply-chain competition and negative-spillover from environmental effort[J]. Regional Sustainability, 2022, 3(4): 319-334.

Table 2

Basic variables used in this study."

| Variable | Description |

|---|---|

| a | The total market demand potential. |

| θ | The degree of inter-supply-chain competition ranging from 0 to 1. |

| s | The level of environmental effort. |

| η | The coefficient of environmental effort cost. |

| k | The coefficient of negative-spillover effect of environmental effort, that is, the degree of an environmental effort by supply chain 1 shrinks the demand of supply chain 2, the range of k is 0-1. |

| c | The unit manufacturing cost. |

| f | The unit sales cost. |

| qi | The demand for supply chain i. |

| wi | The wholesale price of product i. |

| Mi | The profit of manufacturer i. |

| Ri | The profit of retailer i. |

| Ti | The profit of supply chain i. |

| pi | The retail price of product i. |

Table 3

Influence on equilibrium of negative-spillover from environmental effort."

| Supply chain strucure | (?p1)/?k | (?p2)/?k | (?s)/?k | (?w1)/?k | (?w2)/?k | (?T1)/?k | (?T2)/?k | (?M1)/?k | (?M2)/?k | (?R1)/?k | (?R2)/?k |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CC | - | N | - | \ | \ | - | N | - | N | \ | \ |

| DC | - | N | - | - | \ | - | N | - | N | - | \ |

| CD | - | N | - | \ | - | - | N | - | N | \ | N |

| DD | - | - | - | - | N | - | N | - | N | - | N |

Table 4

Influence of degree of competition on equilibrium solution."

| Supply chain sturcture | Variable | k=0.5 | k=1.0 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| θ=0.1 | θ=0.3 | θ=0.5 | θ=0.7 | θ=0.9 | θ=0.1 | θ=0.3 | θ=0.5 | θ=0.7 | θ=0.9 | ||

| CC | p1 | 8.77 | 7.43 | 6.68 | 6.18 | 5.81 | 8.54 | 7.10 | 6.36 | 5.89 | 5.54 |

| p2 | 4.44 | 4.72 | 4.73 | 4.66 | 4.57 | 3.70 | 3.93 | 4.18 | 4.25 | 4.23 | |

| s | 6.61 | 5.12 | 4.29 | 3.75 | 3.36 | 6.24 | 4.52 | 3.64 | 3.09 | 2.71 | |

| T1 | 28.3 | 24.23 | 21.85 | 20.17 | 18.85 | 27.33 | 22.77 | 20.36 | 18.75 | 17.54 | |

| T2 | 6.55 | 9.61 | 11.19 | 12.05 | 12.51 | 1.33 | 4.84 | 7.14 | 8.57 | 9.47 | |

| DC | p1 | 9.32 | 8.41 | 7.80 | 7.34 | 6.97 | 9.23 | 8.26 | 7.63 | 7.17 | 6.81 |

| p2 | 5.42 | 5.43 | 5.34 | 5.21 | 5.09 | 4.92 | 5.09 | 5.08 | 5.01 | 4.92 | |

| s | 2.39 | 2.01 | 1.77 | 1.60 | 1.46 | 2.30 | 1.84 | 1.56 | 1.37 | 1.22 | |

| T1 | 16.73 | 15.32 | 14.32 | 13.52 | 12.83 | 16.44 | 14.81 | 13.75 | 12.95 | 12.29 | |

| T2 | 12.92 | 15.29 | 16.71 | 17.6 | 18.15 | 9.38 | 12.41 | 14.26 | 15.46 | 16.24 | |

| CD | p1 | 8.82 | 7.65 | 7.04 | 6.65 | 6.36 | 8.48 | 7.18 | 6.57 | 6.21 | 5.95 |

| p2 | 5.67 | 6.10 | 6.16 | 6.10 | 6.00 | 3.78 | 5.04 | 5.54 | 5.56 | 5.55 | |

| s | 6.59 | 5.16 | 4.41 | 3.93 | 3.59 | 6.04 | 4.28 | 3.43 | 2.91 | 2.55 | |

| T1 | 29.13 | 26.50 | 25.20 | 24.33 | 23.66 | 27.70 | 24.30 | 22.86 | 22.02 | 21.41 | |

| T2 | 4.95 | 7.30 | 8.64 | 9.52 | 10.13 | 1.16 | 4.01 | 5.88 | 7.12 | 8.01 | |

| DD | p1 | 9.45 | 8.77 | 8.34 | 8.02 | 7.76 | 9.32 | 8.53 | 8.08 | 7.76 | 7.51 |

| p2 | 7.14 | 7.19 | 7.12 | 7.01 | 6.89 | 6.40 | 6.71 | 6.76 | 6.72 | 6.65 | |

| s | 2.40 | 2.06 | 1.85 | 1.70 | 1.58 | 2.27 | 1.80 | 1.52 | 1.33 | 1.18 | |

| T1 | 17.36 | 16.95 | 16.70 | 16.47 | 16.24 | 16.92 | 16.14 | 15.77 | 15.51 | 15.28 | |

| T2 | 9.70 | 11.68 | 13.12 | 14.24 | 16.16 | 7.11 | 9.60 | 11.33 | 12.63 | 13.68 | |

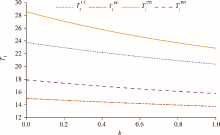

Fig. 1.

Changes of the profit of supply chain 1 (T1) associated with the coefficient of negative-spillover from environmental effort (k) under the four scenarios. T1CC, the profit of supply chain 1 when both supply chains are centralized; T1DC, the profit of supply chain 1 when the leader supply chain 1 is decentralized and the follower supply chain 2 is centralized; T1CD, the profit of supply chain 1 when the leader supply chain 1 is centralized and the follower supply chain 2 is decentralized; T1DD, the profit of supply chain 1 when both supply chains are decentralized."

Fig. 2.

Changes of the profit of supply chain 2 (T2) associated with the coefficient of negative-spillover from environmental effort (k) under the four scenarios. T2CC, the profit of supply chain 2 when both supply chains are centralized; T2DC, the profit of supply chain 2 when the leader supply chain 1 is decentralized and the follower supply chain 2 is centralized; T2CD, the profit of supply chain 2 when the leader supply chain 1 is centralized and the follower supply chain 2 is decentralized; T2DD, the profit of supply chain 2 when both supply chains are decentralized."

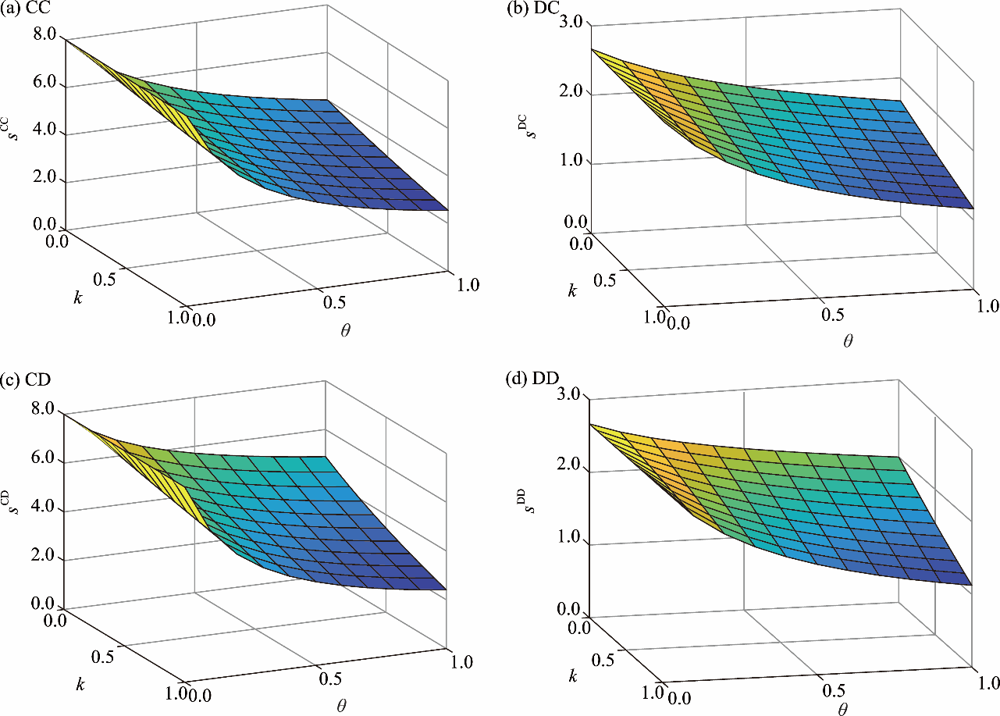

Fig. 3.

Changes of the level of environmental effort (s) associate with the degree of competition (θ) and the coefficient of negative-spillover from environmental effort (k) under the CC (a), DC (b), CD (c), and DD (d) scenarios. sCC, the level of environmental effort under the scenario of both supply chains are centralized; sDC, the level of environmental effort under the scenario of the leader supply chain 1 is decentralized and the follower supply chain 2 is centralized; sCD, the level of environmental effort under the scenario of the leader supply chain 1 is centralized and the follower supply chain 2 is decentralized; sDD, the level of environmental effort under the scenario of both supply chains are decentralized."

| [1] |

Ahi, P., Searcy, C., 2013. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean Prod. 52, 329-341.

doi: 10.1016/j.jclepro.2013.02.018 |

| [2] |

Azevedo, S.G., Carvalho, H., Machado, V.C., 2011. The influence of green practices on supply chain performance: A case study approach. Transport Res. E-Log. 47(6), 850-871.

doi: 10.1016/j.tre.2011.05.017 |

| [3] |

Basiri, Z., Heydari, J., 2017. A mathematical model for green supply chain coordination with substitutable products. J. Clean Prod. 145, 232-249.

doi: 10.1016/j.jclepro.2017.01.060 |

| [4] |

Bernstein, F., Song, J.S., Zheng, X.N., 2009. Free riding in a multi-channel supply chain. Nav. Res. Log. 56(8), 745-765.

doi: 10.1002/nav.20379 |

| [5] |

Blalock, G., Veloso, F.M., 2007. Imports, productivity growth, and supply chain learning. World Dev. 35(7), 1134-1151.

doi: 10.1016/j.worlddev.2006.10.009 |

| [6] |

Brandenburg, M., Rebs, T., 2015. Sustainable supply chain management: a modeling perspective. Ann. Oper. Res. 229(1), 213-252.

doi: 10.1007/s10479-015-1853-1 |

| [7] |

Cao, Y., Tao, L., Wu, K., et al., 2020. Coordinating joint greening efforts in an agri-food supply chain with environmentally sensitive demand. J. Clean Prod. 277, 123883, doi: 10.1016/j.jclepro.2020.123883.

doi: 10.1016/j.jclepro.2020.123883 |

| [8] |

Chen, K.B., Liang, J., Li, J.B., 2012. Information structures and pricing decisions in competing supply chains. J. Syst. Sci. Syst. Eng. 21(2), 226-254.

doi: 10.1007/s11518-012-5193-2 |

| [9] |

Chen, X., Zhang, H., Zhang, M., et al., 2017. Optimal decisions in a retailer Stackelberg supply chain. Int. J. Prod. Econ. 187, 260-270.

doi: 10.1016/j.ijpe.2017.03.002 |

| [10] |

Christopher, M., 2000. The agile supply chain-Competing in volatile markets. Ind. Market. Manag. 29(1), 37-44.

doi: 10.1016/S0019-8501(99)00110-8 |

| [11] |

Costantini, V., Crespi, F., Marin, G., et al., 2017. Eco-innovation, sustainable supply chains and environmental performance in European industries. J. Clean Prod. 155, 141-154.

doi: 10.1016/j.jclepro.2016.09.038 |

| [12] |

Das, D., 2018. The impact of sustainable supply chain management practices on firm performance: Lessons from Indian organizations. J. Clean Prod. 203, 179-196.

doi: 10.1016/j.jclepro.2018.08.250 |

| [13] | Fernando, Y., Wah, W.X., 2017. The impact of eco-innovation drivers on environmental performance: Empirical results from the green technology sector in Malaysia. Sustain. Prod. Consump. 12, 27-43. |

| [14] |

Galpin, T., Whitttington, J.L., Bell, G., 2015. Is your sustainability strategy sustainable? Creating a culture of sustainability. Corporate Governance-The International Journal of Business in Society. 15(1), 1-17.

doi: 10.1108/CG-01-2013-0004 |

| [15] |

Gao, J.H., Han, H.S., Hou, L.T., et al., 2016. Pricing and effort decisions in a closed-loop supply chain under different channel power structures. J. Clean Prod. 112, 2043-2057.

doi: 10.1016/j.jclepro.2015.01.066 |

| [16] |

Ge, Z.H., Hu, Q.Y., Xia, Y.S., 2014. Firms’ R&D cooperation behavior in a supply chain. Prod. Oper. Manag. 23(4), 599-609.

doi: 10.1111/poms.12037 |

| [17] | Genovese, A., Acquaye, A.A., Figueroa, A., et al., 2017. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega-Int. J. Manage. S. 66, 344-357. |

| [18] |

Giannakis, M., Papadopoulos, T., 2016. Supply chain sustainability: A risk management approach. Int. J. Prod. Econ. 171(Part 4), 455-470.

doi: 10.1016/j.ijpe.2015.06.032 |

| [19] |

Gligor, D., Gligor, N., Holcomb, M., et al., 2019. Distinguishing between the concepts of supply chain agility and resilience: A multidisciplinary literature review. Int. J. Logist Manag. 30(2), 467-487.

doi: 10.1108/IJLM-10-2017-0259 |

| [20] |

Golicic, S.L., Smith, C.D., 2013. A meta-analysis of environmentally sustainable supply chain management practices and firm performance. J. Supply Chain Manag. 49(2), 78-95.

doi: 10.1111/jscm.12006 |

| [21] |

Green, K.W., Zelbst, P.J., Meacham, J., et al., 2012. Green supply chain management practices: impact on performance. Supply Chain Management. 17(3), 290-305.

doi: 10.1108/13598541211227126 |

| [22] |

Hänninen, N., Karjaluoto, H., 2017. Environmental values and customer-perceived value in industrial supplier relationships. J. Clean Prod. 156, 604-613.

doi: 10.1016/j.jclepro.2017.04.081 |

| [23] |

Hearnshaw, E.J.S., Wilson, M.M.J., 2013. A complex network approach to supply chain network theory. Int. J. Oper. Prod. Man. 33(3-4), 442-469.

doi: 10.1108/01443571311307343 |

| [24] |

Herczeg, G., Akkerman, R., Hauschild, M.Z., 2018. Supply chain collaboration in industrial symbiosis networks. J. Clean Prod. 171, 1058-1067.

doi: 10.1016/j.jclepro.2017.10.046 |

| [25] |

Hong, J.T., Zhang, Y.B., Ding, M.Q., 2018. Sustainable supply chain management practices, supply chain dynamic capabilities, and enterprise performance. J. Clean Prod. 172, 3508-3519.

doi: 10.1016/j.jclepro.2017.06.093 |

| [26] |

Isaksson, O.H.D., Simeth, M., Seifert, R.W., 2016. Knowledge spillovers in the supply chain: Evidence from the high tech sectors. Res. Policy. 45(3), 699-706.

doi: 10.1016/j.respol.2015.12.007 |

| [27] |

Klassen, R.D., Vachon, S., 2003. Collaboration and evaluation in the supply chain: The impact on plant-level environmental investment. Prod. Oper. Manag. 12(3), 336-352.

doi: 10.1111/j.1937-5956.2003.tb00207.x |

| [28] |

Kopnina, H., 2018. Education for sustainable development (ESD): the turn away from ‘Environment’ in environmental education? Environ. Educ. Res. 18(5), 699-717.

doi: 10.1080/13504622.2012.658028 |

| [29] |

Kovács, G., 2008. Corporate environmental responsibility in the supply chain. J. Clean Prod. 16(15), 1571-1578.

doi: 10.1016/j.jclepro.2008.04.013 |

| [30] |

Li, B., Zhu, M.Y., Jiang, Y.S., et al., 2016. Pricing policies of a competitive dual-channel green supply chain. J. Clean Prod. 112, 2029-2042.

doi: 10.1016/j.jclepro.2015.05.017 |

| [31] |

Li, B.X., Zhou, Y.W., Wang, X.Z., 2013. Equilibrium analysis of distribution channel structures under power imbalance and asymmetric information. Int. J. Prod. Res. 51(9), 2698-2714.

doi: 10.1080/00207543.2012.737954 |

| [32] |

Li, J.L., Liu, L.W., 2008. Supply chain coordination with manufacturer’s limited reserve capacity: An extended newsboy problem. Int. J. Prod. Econ. 112(2), 860-868.

doi: 10.1016/j.ijpe.2007.07.006 |

| [33] |

Lieder, M., Rashid, A., 2016. Towards circular economy implementation: a comprehensive review in context of manufacturing industry. J. Clean Prod. 115, 36-51.

doi: 10.1016/j.jclepro.2015.12.042 |

| [34] |

Lin, M.H., Hu, J.Y., Tseng, M.L., et al., 2016. Sustainable development in technological and vocational higher education: balanced scorecard measures with uncertainty. J. Clean Prod. 120, 1-12.

doi: 10.1016/j.jclepro.2015.12.054 |

| [35] |

Martínez-Jurado, P.J., Moyano-Fuentes, J., 2014. Lean management, supply chain management and sustainability: a literature review. J. Clean Prod. 85, 134-150.

doi: 10.1016/j.jclepro.2013.09.042 |

| [36] |

Mathiyazhagan, K., Govindan, K., NoorulHaq, A., et al., 2013. An ISM approach for the barrier analysis in implementing green supply chain management. J. Clean Prod. 47, 283-297.

doi: 10.1016/j.jclepro.2012.10.042 |

| [37] |

Modak, N.M., Panda, S., Sana, S.S., 2016. Two-echelon supply chain coordination among manufacturer and duopolies retailers with recycling facility. Int. J. Adv. Manuf. Tech. 87(5-8), 1531-1546.

doi: 10.1007/s00170-015-8094-y |

| [38] |

Mudgal, R.K., Shankar, R., Talib, P., et al., 2010. Modelling the barriers of green supply chain practices: an Indian perspective. International Journal of Logistics Systems and Management. 7(1), 81-107.

doi: 10.1504/IJLSM.2010.033891 |

| [39] |

Niosi, J., Zhegu, M., 2005. Aerospace clusters: local or global knowledge spillovers? Industry and Innovation. 12(1), 5-29.

doi: 10.1080/1366271042000339049 |

| [40] |

Olsen, M.C., Slotegraaf, R.J., Chandukala, S.R., 2014. Green claims and message frames: how green new products change brand attitude. J. Marketing. 78(5), 119-137.

doi: 10.1509/jm.13.0387 |

| [41] | Pakseresht, M., Shirazi, B., Mahdavi, I., et al., 2020. Toward sustainable optimization with stackelberg game between green product family and downstream supply chain. Sustain. Prod. Consump. 23, 198-211. |

| [42] |

Rajeev, A., Pati, R.K., Padhi, S.S., et al., 2017. Evolution of sustainability in supply chain management: A literature review. J. Clean Prod. 162, 299-314.

doi: 10.1016/j.jclepro.2017.05.026 |

| [43] |

Saharidis, G.K.D., Kouikoglou, V.S., Dallery, Y., 2009. Centralized and decentralized control polices for a two-stage stochastic supply chain with subcontracting. Int. J. Prod. Econ. 117(1), 117-126.

doi: 10.1016/j.ijpe.2008.10.001 |

| [44] |

Sajjad, A., Eweje, G., Tappin, D., 2015. Sustainable supply chain management: motivators and barriers. Bus. Strateg. Environ. 24(7), 643-655.

doi: 10.1002/bse.1898 |

| [45] |

Sauvé, S., Bernard, S., Sloan, P., 2016. Environmental sciences, sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 17, 48-56.

doi: 10.1016/j.envdev.2015.09.002 |

| [46] |

Silvestre, B.S., 2015. Sustainable supply chain management in emerging economies: Environmental turbulence, institutional voids and sustainability trajectories. Int. J. Prod. Econ. 167, 156-169.

doi: 10.1016/j.ijpe.2015.05.025 |

| [47] |

Strezov, V., Evans, A., Evans, T.J., 2017. Assessment of the economic, social and environmental dimensions of the indicators for sustainable development. Sustain. Dev. 25(3), 242-253.

doi: 10.1002/sd.1649 |

| [48] |

Tallon, P.P., 2011. Value chain linkages and the spillover effect of strategic information technology alignment: a process-level view. J. Manage. Inform. Syst. 28(3), 9-44.

doi: 10.2753/MIS0742-1222280301 |

| [49] | Taylor, T.A., 2002. Supply chain coordination under channel rebates with sales effort effects. Manage. Sci. 48(8), 992-1007. |

| [50] |

Testa, F., Iraldo, F., 2010. Shadows and lights of GSCM (green supply chain management): determinants and effects of these practices based on a multi-national study. J. Clean Prod. 18(10-11), 953-962.

doi: 10.1016/j.jclepro.2010.03.005 |

| [51] | Tsay, A.A., Agrawal, N., 2000. Channel dynamics under price and service competition. Manufacturing & Service Operations Management. 2(4), 372-391. |

| [52] |

van den Bergh, J.C.J.M., 2010. Externality or sustainability economics? Ecol. Econ. 69(11), 2047-2052.

doi: 10.1016/j.ecolecon.2010.02.009 |

| [53] |

Walker, H., Di Sisto, L., McBain, D., 2008. Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors. J. Purch. Supply Manag. 14(1), 69-85.

doi: 10.1016/j.pursup.2008.01.007 |

| [54] |

Wang, C.X., Wang, W., Huang, R.B., 2017. Supply chain enterprise operations and government carbon tax decisions considering carbon emissions. J. Clean Prod. 152, 271-280.

doi: 10.1016/j.jclepro.2017.03.051 |

| [55] | Wang, J., Dai, J., 2018. Sustainable supply chain management practices and performance. Industrial Management & Data System. 118(1), 2-21. |

| [56] |

Wooi, G.C., Zailani, S., 2010. Green supply chain initiatives: investigation on the barriers in the context of SMEs in Malaysia. International Business Management. 4(1), 20-27.

doi: 10.3923/ibm.2010.20.27 |

| [57] |

Wu, Y.C., Wang, J.G., Li, C.H., et al., 2018. Optimal supply chain structural choice under horizontal chain-to-chain competition. Sustainability. 10(5), 1330, doi: 10.3390/su10051330.

doi: 10.3390/su10051330 |

| [58] |

Xing, D.H., Liu, T.M., 2012. Sales effort free riding and coordination with price match and channel rebate. Eur. J. Oper. Res. 219(2), 264-271.

doi: 10.1016/j.ejor.2011.11.029 |

| [59] |

Xu, L., Wang, C.X., Li, H., 2017. Decision and coordination of low-carbon supply chain considering technological spillover and environmental awareness. Sci. Rep. 7, 3107, doi: 10.1038/s41598-017-03270-2.

doi: 10.1038/s41598-017-03270-2 pmid: 28596560 |

| [60] |

Zhang, F.F., Zhang, Z.X., Xue, Y.W., et al., 2020. Dynamic green innovation decision of the supply chain with innovating and free-riding manufacturers: cooperation and spillover. Complexity. 8937847, doi: 10.1155/2020/8937847.

doi: 10.1155/2020/8937847 |

| [61] | Zhao, F., 2004. Siemens’ business excellence model and sustainable development. Measuring Business Excellence. 8(2), 55-64. |

| [62] |

Zhao, X., Shi, C.M., 2011. Structuring and contracting in competing supply chains. Int. J. Prod. Econ. 134(2), 434-446.

doi: 10.1016/j.ijpe.2009.11.016 |

| [63] |

Zhu, Q.H., Sarkis, J., Lai, K.H., 2008. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 111(2), 261-273.

doi: 10.1016/j.ijpe.2006.11.029 |

| [64] |

Zhu, Q.H., Sarkis, J., Lai, K.H., 2012. Examining the effects of green supply chain management practices and their mediations on performance improvements. Int. J. Prod. Res. 50(5), 1377-1394.

doi: 10.1080/00207543.2011.571937 |

| No related articles found! |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

REGSUS Wechat

REGSUS Wechat

新公网安备 65010402001202号

新公网安备 65010402001202号